Review Article - (2023) Volume 14, Issue 2

Abstract

Along with its phytochemical and pharmacological capabilities, polyherbal preparations have been utilized everywhere in the entire globe. Polyherbal treatment or herb-herb combo is yet another term for it. This study compiles a list of commercially and non-commercial polyherbal compositions from everywhere in the globe, which dissolve quickly without the use of water. These tablets dissolve and/or disintegrate quickly in the mouth. FDTs are easy to create and give, have no negative impacts, as well as provide an immediate release, and improve bioavailability, resulting in better patient satisfaction. For juvenile, elderly and immobile patients, fast disintegrating tablets have been designed. FDTs can be made using a range of methodologies. Herbal medications account for a significant portion of India’s legally acknowledged healthcare system. Because of the formulation’s acceptance and use, many FDT techniques have been proposed. All of the important aspects of polyherbal formulation are described in this article.

Keywords

Fast Disintegrating Tablet (FDT), Herbal plants, Herbal superdisintegrants, Holistic medicine

Introduction

Fast disintegrating tablets, also known as oral disintegrating tablets, are the best formulation that makes use of the “oral mucosa.” An ODT (Oral Disintegrating Tablet) put on the tongue should disperse or disintegrate in far less than 180 seconds, as per European pharmacopeia. FDDDS (Fast Disintegrating Drug Delivery System) is a revolutionary idea that combines the features of solid and liquid preparations while also providing advantages over previous pharmaceutical formulations. Fast disintegrating tablets offer improved patient satisfaction, a fast duration of action, enhanced bioavailability, and better stability, making it an attractive dose form on the marketplace today. The information regarding the Fast Disintegrating Tablet (FDT) was given inside this review in an easy-to-understand way (Allen L and Ansel HC 2013; Wal A, et al., 2021).

Literature Review

The optimal property for a fast disintegrating tablet

An immediate or fast disintegrating tablet that dissolves in the mouth in contact with saliva in less than 60 seconds, ideally in less than 40 seconds, resulting in a liquid suspension that is readily ingested. More commonly, the phrase “orally disintegrating tablets” is used. Estimates suggest that half of the population has difficulty swallowing medications. As a result of the challenges, the recommended prescription is not followed, and the treatment’s performance suffers (Jain NK, Sharma SN, et al., 1998).

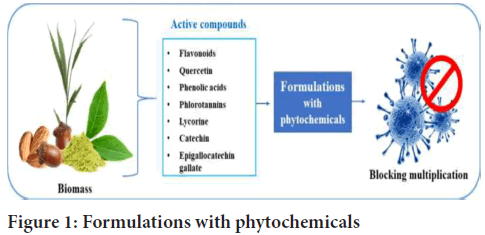

In a brief, oral disintegrating tablets are convenient to use for individuals who are concerned regarding chewing or who prefer not to drink the water while taking medicine. Recent advancements in innovative pharmaceutical delivery (NDDS) aim to enhance patient satisfaction and enhance drug molecule effectiveness and safety by providing a pleasant dose form that is easy to give. Oral disintegrating tablets are one of the many options. Oral disintegrating tablets are solid unit dosage forms that disintegrate or dissolve immediately in the mouth without using water, chewing, and swallowing. Fast Disintegrating Tablet (FDT) dose forms have been established to fulfill the demands of patients while maintaining efficiency. The FDTs were developed to assist individuals who already have trouble swallowing traditional capsules or tablets (Figure 1) (Yadav ND, et al., 2010; Ratnaparkhi MP, et al., 2019). Fast-disintegrating tablets provide the following advantages FDTs are solid unit dosage form that enables optimal drug and precision administration. They’re a great alternative to regular tablets, with a dosage that’s appropriate for the elderly and children.

Figure 1: Formulations with phytochemicals

• It has a rapid effect because that starts to melt as soon as it happens into buccal cavity, is instantly absorbed in the oral mucosa, and melts quickly, giving it a faster action.

• The bioavailability of the medications is altered as a consequence of pre-gastric intake, and fewer dosages are needed, resulting in improved patient compliance and clinical findings.

• Fast-disintegrating tablets can be used at any time and do not need the usage of water. They are a practical alternative for travelers and busy persons who do not have rapid access to clean drinking water, leading to higher patient satisfaction.

• They are easy to enforce because they are solid unit dose forms, and they are especially helpful for old, juvenile, timid, and dysphasic people.

• There seems to be no risk of asphyxia associated with physical congestion in the airways when ingesting.

• They disintegrate completely in the mouth, leaving no trace, providing a delightful experience on the tongue and boosting tablet consumer acceptability.

• They are less prone to environmental alterations, making them highly stable.

• They are reasonably priced since they do not require additional or costly packaging.

• It provides varieties of products, promotion, brand extension, distinctiveness, and life span maintenance.

• They are made by a unique technology since they are used in the development of Over-The-Counter (OTC) pharmaceuticals, prescription drugs, and veterinary meds.

• They’re convenient to carry so their dosage forms are less prone to environmental factors and also don’t utilize water to use (Pahwa R, et al., 2010; Kumar VD, et al., 2011).

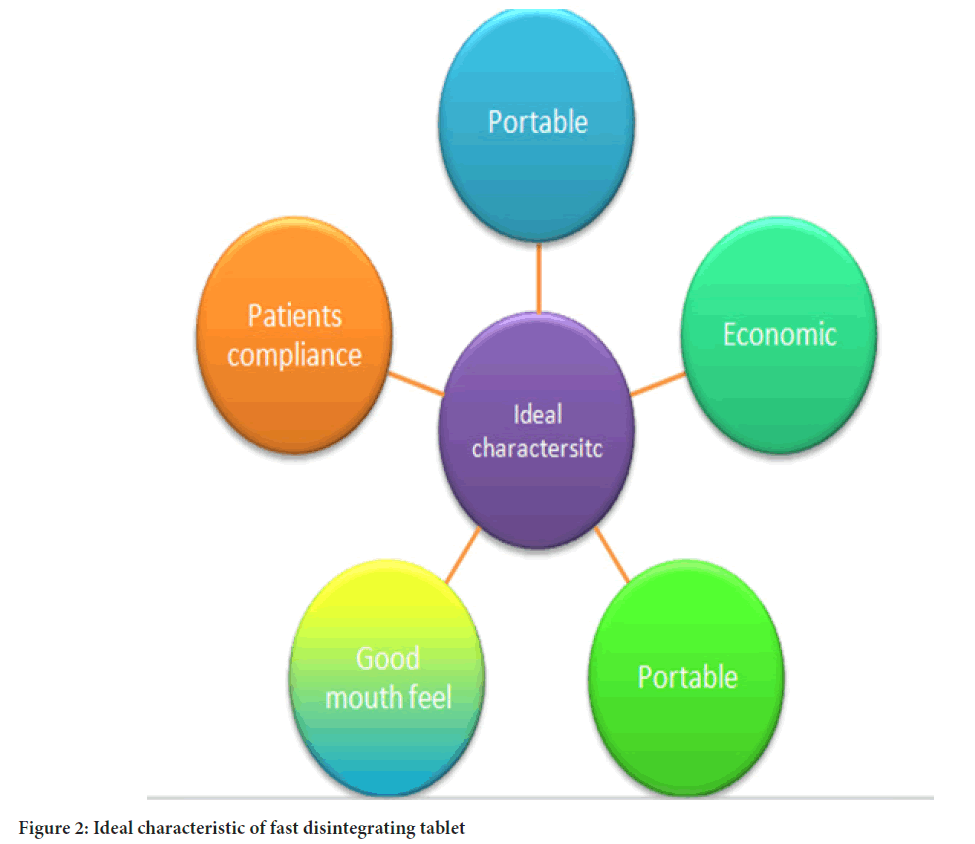

Fast disintegrating tablets include a biodegradable polymer (Figure 2). Natural polymers are advantageous due to their proven biomedical applications and safe. Organic gums are one of the most widely used aqueous polymers due to their low cost and legislative approvals. Polymers are frequently employed in floating medicine distribution systems to target drug delivery to a particular part of the intestinal tract, like the stomach. These polymers are also harmless, chemically adaptable, and also susceptible to producing gels (Kumar VD, et al., 2011).

Figure 2: Ideal characteristic of fast disintegrating tablet

Benefits of natural polymers

The following are just a few of the many benefits of using natural plantbased goods-

i. Recyclable: Because they are naturally occurring and generated by all living beings, they are recyclable.

ii. Biocompatibility and non-toxicity: These natural ingredients are sugar polysaccharides repeated.

iii. Low price: Using natural resources is less costly. The cost of manufacture is lower when compared to synthetic materials. Horticulture is very essential to India and so many other underdeveloped regions, and they spend a lot on it.

iv. Eco-friendly processing: Natural compounds originating from a wide range of plant resources are widely employed in Pharma companies and are gathered in large quantities due to the comparatively easy production procedures needed.

v. Local availability: Given the wide range of uses in industries, the government encourages the use of plants as medical excipients and provides facilities for the mass manufacture of gum and mucilage.

vi. Patient’s acceptance as well as social appreciation: Organic resources have fewer side effects and negative repercussions than synthetic materials (Beneke CE, et al., 2009).

Classification of polymers used in the fast disintegrating tablet

Natural polymer: This is a selection of products made from the plant for the following reasons; plant-based materials are a great replacement for synthetic materials.

a) Accessibility in the immediate vicinity

b) Bio-acceptability

c) Eco-friendliness

d) Having renewable and a reduced cost than manmade items

Natural polymers used in fast disintegrating tablets

The natural polymers used in fast disintegrating tablets are mentioned below (Table 1)

| S.No | Natural polymer | Marketed drug | Disintegration time | Concentration use | Reference |

|---|---|---|---|---|---|

| 1 | Chitin and chitosan | Cinnarizine | 60 sec | 3% w/w | Nagar M and Yadav AV, 2009 |

| 2 | Guar gum | Glipizide | 30 sec | 1% w/w | Jha AK and Chetia D, 2012 |

| 3 | Gum karaya | Amplodipine, granisetron hydrochloride | 17.10 sec | 4% w/w | Suresh S, et al., 2011 |

| 4 | Agar and treated agar 20 sec | Theophylline | 20 sec | 1%-2% w/w | Sharma V, et al., 2010 |

| 5 | Fenugreek seed mucilage | Metformine hydrochloride | 15.6 sec | 4% w/w | Sukhavasi S and Kishore VS, 2012 |

| 6 | Soy polysaccharide | Lomoxicam | 12 sec | 8% w/w | Taksande JB, et al., 2013 |

| 7 | Gellan gum | Metronidazole | 15.5 sec | 4% w/w | Prajapati ST, et al., 2014 |

| 8 | Mango peel pectin | Aceclofenac | 11.59 sec | 0.1%-4% w/w | Malviya R, et al., 2010 |

| 9 | Lepidium sativum mucilage | Nimesulide | 17 sec | 5%-15% w/w | Kaur L, et al., 2014 |

| 10 | Plantago ovata seed mucilage | Granisetron HCl | 17.10 sec | 5% w/w | Kishore VS, et al., 2013 |

| 11 | Aegle marmelos gum | Aceclofenac | 8-18 min | 6% w/w | Bharathi A, et al., 2012 |

| 12 | Locust bean gum | Nimesulide | 13 sec | 10% w/w | Kapoor M, et al., 2017 |

| 13 | Lepidium sativum | Nimesulide | 17 sec | 10% w/w | Jhansi M, 2013 |

| 14 | Mangifera indica gum | Metformine HCl, paracetamol | 3-8 min | 6% w/w | Ravi KN, et al., 2011 |

| 15 | Hibiscus rosasinensis mucilage | Aceclofenac | 20 sec | 6% w/w | Jayapirakasam SV, et al., 2018 |

| 16 | Dehydrated banana powder | Ondansetron propanolol, gabapentin | 15-36 sec | 6% w/w | Soni A and Raju L, 2015 |

Table 1: Natural polymer used in fast dissolving tablets

Chitin and chitosan: Chitin is a polymer found in crab and shrimp shells. It has an amino group that is covalently bonded to an acetyl group, unlike chitosan. Commercially, chitosan is manufactured by deacetylating chitin, a structural component of crustacean exoskeletons (such as crabs and shrimp) and fungal cell walls.

When chitin was introduced to conventional tablets, researchers discovered that the pills crumbled after 5 to 10 minutes, independent of the drug’s solubility. Chitosan is the most well-known natural polysaccharide, with several uses in the pharmaceutical industry (Kumar SA, et al., 2012).

Guar gum: Guar gum is made up largely of high molecular weight polysaccharides-galactomannans and obtained from the endosperm of the seed of the guar plant, Cyamopsis tetragonoloba (L) Taub. In most areas of the globe, it is used as a thickener, stabilizer, and emulsifier. Jaguar gum is a form of gum that develops organically and is sold under the Jaguar brand. It’s a sugar-based basic polymer that’s gratis and completely soluble, and it’s been approved for use in food. It is unaltered by pH, water content, or the solubility of the core tablets. This is not always pure white in alkali tablets and can vary in color from off-white to brownish. It has a proclivity towards fading with duration.

Gum karaya: It is a botanical gum generated as an exudate by plants of the species Sterculia, which is an acidic polysaccharide, mainly composed of rhamnose, sugars galactose, and galacturonic acid. Because of its viscosities, gum cannot be utilized as an adhesive or disintegrant in a conventional solid dosage form. Gum karaya’s promise like a tablet disintegrant has been researched (Bruscato FN, et al., 1978).

Synthetic gum karaya, according to multiple researches, allows tablets to disintegrate fast. It can be employed as a substitute superdisintegrant to available on the market as artificial and synthetically produced superdisintegrants for its minimal cost, biocompatibility, and simplicity of supply (Batham P, et al., 1986).

Agarandtreatedagar: Gelidium amansii plus a variety of other red algae varieties such as Pterocladia and Gracilaria are used to make it. Agar is a mucilaginous substance that occurs in the form of divests, sheet flakes, and fine powder. It is a pale yellow to practically white, inodorous, and has a mucilage flavor. Agar is made up of two polysaccharides-agar pectin and agarose. Agar mixtures’ fluidity is controlled by agar pectin, whereas gel vigor is controlled by agarose. Because of its high gel vigor, agar is a prudent option as disintegrants (Shirwaikar A, et al., 2008).

Polysaccharide soy: It’s a biological superdisintegrants that doesn’t include any starch or sugar, so it’s safe to use in healthy foods. Shirwaikar A, et al., 2008 evaluated polysaccharide soy as a disintegrant in tablets made by direct compression with dicalcium phosphate dehydrate and lactose as fillers. Cross-linked sodium carboxymethyl cellulose and corn starch have been utilized as reference disintegrants. Polysaccharide soy works effectively as a disintegrant in direct compression formulas, with results equivalent to cross-linked CMC.

Gellan gum: Pseudomonas elodea produces gellan gum, which is a liquid polymer. Gellan gum is a polysaccharide gum produced by a virgin Pseudomonas elodea colony and containing a tetrasaccharide functional group. In 1997, Antony and Sanghavi evaluated the efficacy of gellan gum as a disintegrant to that of common disintegrants including such dehydrated corn starch, Avicel (pH 10.2), Ac-di-sol, and Kollidon CL. Gellan gum’s immediate swelling qualities whenever it reacts with water, including its highly aqueous nature, may have helped to the tablet’s breakdown. The tablet’s complete disintegration has shown to be gellan gum as an excellent disintegrant (Setia A, et al., 2011).

Mango peels pactin: Mango peel, which makes up approximately 25 percent of all mango biowaste, has been revealed to be a great source of high-quality pectin extraction, film manufacturing, and passable jelly. Pectin is a hydrophilic inverted heteropolysaccharide with an inverted heteropolysaccharide in the middle. Due to its decent dissolution rate and increased water content, Malviya, et al., 2011 revealed that mango peel pectin is a nice choice for disintegrants; it’s just not as potent as chemically synthesized disintegrants. Even so, it could be used in the composition of quick disintegrating tablets for its decent dissolution rate and continued to increase swelling indicator.

Lepidium sativum mucilage: Asaliyo is the Indian name for the plant Lepidium sativum, which is frequently used as an ayurvedic remedy. It is affordable and widely accessible on the market. Other elements include leaves, roots, soil, seeds, and more. Seeds include increased quantities of mucilage, the dimeric imidazole alkaloids, imidazole semilepidinoside A and B. Binding, dissolving, gelling, as well as other features of Lepidium sativum mucilage have been reported (Prabhu KH, et al., 2010).

Plantago ovata seed mucilage: Psyllium, often known as ispaghula, is the general term for several Plantago species whose seeds are economically utilized to make mucilage. Mucilage from Plantago ovata has several desirable properties, such as binding, disintegrating, and retaining characteristics. In research, fast-dissolving amlodipine besylate tablets were produced employing a direct compression method and different amounts of Plantago ovata mucilage as biological super disintegrants. All formulations were evaluated for weight fluctuation, toughness, deformability, disintegration time, drug loading, and solubility. The optimized formulation has a disintegration time of 11.69 sec and a dissolving duration of 15 mins in vitro. In vitro breakdown time will decrease as organic superdisintegrant concentration rises (Rinaudo M, 2006).

Aegle marmelos gum: This is made from the fruits of the Aegle marmelos tree and dissolves sooner and more evenly than croscarmellose sodium. The mature fruit pulp has a mucilaginous, astringent flavor and is dark red. The pulp contains vitamins C and A, proteins, carbohydrates, angelenine, marmeline, dictamine, O-methyl halfordinol. AMG is prepared by heating it. It helps drugs that aren’t highly soluble to become more soluble. It induces considerable changes in glutathione levels in the liver, kidney, abdomen. Similarly, it reduces blood insulin and liver glycogen, lowers lipid peroxidation, promotes macrophage activity, and raises blood sugar levels and glycosylated hemoglobin in diabetes patients. The pure bael gum polysaccharide contains L-rhamnose (6.5%), D-galacturonic acid (7%), D-galactose (71%), D-galacturonic acid (7%), and L-arabinose (6.5%) (Kumar R, et al., 2019).

Locust bean gum: It’s referred to as carob bean gum. It was a galactomannan vegetable gum made in the Mediterranean from carob tree seeds. Locust bean gum is a food-safe thickening and gelling ingredient as well as bio glue that improves solubility. The gum is an odorless white to pale yellow powder. Most organic solvents, including ethanol, are intractable in it. It is soluble in water at room temperature and in lukewarm water, but it requires heating to temperatures for 10 minutes to achieve optimal solubility (Kumar R, et al., 2009; Antony PJ and Sanghavi NM, 1997).

Ficus indica fruit mucilage: Frucus indica fruit mucilage, which is generated from the pulp of the Ficus indica fruit, is the super disintegrant. Ficus indica is a huge tree with spreading branches and arial origins that may reach up to 3 m tall and is highly fast-growing. The Ficus indica tree produces cherry-sized fruits. It is nutritious as well as soothing. The caloric content of the dried and uncooked Ficus indica fruit is 230 kcal (963 KJ) per 100 gm (3.5 oz) (ounce). Fever, discomfort, inflammation, wound regeneration, blood issues, and urinary difficulties are all treated with it (Lieberman H, et al., 1989; Singh B, 2007; Ghenge G, et al., 2011).

Mangifera indica gum: Mangifera indica is the general name for this plant, which belongs to the Anacardiaceae family. It is a disintegrant, adhesive, suspending agent, an emulsifying agent that is used in a variety of formulations. The gum powder is white to the off in color and soluble in water, although it is practically insoluble in ether, methanol, and ethanol. Each and every part of the tree has medicinal benefits, which can be used for diuretic treatment, urethritis, asthma, and diarrhea (Kulkarni U and Rao NG, 2011; Malik K, et al., 2011).

Hibiscus rosasinensin mucilage and treated agar: This is also called as shoe flower plant, China rose, and Chinese hibiscus, and it’s a member of the family Malvaceae. Mucilages contain thickeners, suspending agents, water retention agents, and disintegrants. The plant is easy to find, and its leaves produce mucilage, which contains L-rhamnose, D-glucuronic acid, D-galactose, D-galacturonic acid, and other substances. Yare is agar that has been processed with fresh water for a day (Alam MT, et al., 2014; Ravi KN, et al., 2011).

Dehyated banana powder: The banana is also known as plantain. The Musaceae family species produces DBP, which comes from the banana varieties. It’s used to cure digestive problems and gastroenteritis because it’s high in vitamin A. Vitamin B6 is also present, which helps to alleviate anxiety. It is abundant in carbohydrates and includes potassium, which is needed for even more prominent brain activity. It is also a useful form of energy (Prabakaran L and Sendhil D, 2011; Nagar M and Yadav AV, 2009).

Medicinal plants used in fast disintegrating tablets

Wet granulation was used to manufacture and make polyherbal (Syzygium aromaticum, Piper nigrum, Terminalia belerica, Acacia catechu, Adhatodavasica, Glycyrrhiza glabra) Fast Disintegrating Tablets (FDTs) for the treatment of chest infections. The disintegration time was reduced from 16 minutes to 11 minutes and 25 seconds when the concentration of microcrystalline cellulose was increased from 42.33 mg each tablet to 44.43 mg each tablet. According to the findings, manufactured tablets containing micro-crystalline cellulose disintegrated quicker and better than commercially available tablets (Lavangadivati) (Londhe VY and Umalkar KB, 2012). Based on the research findings of this investigation, it can be stated that nutraceutical clove (Eugenia caryophyllus) tablets containing 160 mg of cross povidone with varied concentrations of disintegrants have a quicker dissolve rate and releasing of a potent medicament for dental issues as well as other therapies. The tablets include a super-disintegrant that disintegrates and dissolves quickly, allowing for a quick start of pain management. By direct compression technique, 25 mg disintegrating tablets were made from aqueous root extract powder of the selected plants Vitex negundo, Solidago virgaurea, Crataeva nurvala, Fumaria indica, Cichorium intybus, Cassia fistula, Ficus hispida, Carica papaya, Boerhavia diffusa, Angelica officinalis (Maurya H and Kumar T, 2019). This formulation contains 200 mg of Tectona grandis Linn’s herbal extract. The disintegration characteristic and dissolve rate of the manufactured herbal quick disintegrating tablets are excellent (Kagalkar AA, et al., 2014).

The Bauhenia veriagata (200 mg per tab) herbal fast disintegrating tablets have a good disintegration and dissolve rate. Crospovidone at a concentration of 3% is appropriate for the creation of herbal fast disintegrating that meets all standards and official restrictions, according to a comparative analysis of numerous superdisintegrants (Kagalkar AA, et al., 2017). Aqueous root extract powder of the selected plants Ligusticum chuanxiong, Albizia myriophylla benth, Glycyrrhiza glabra, Senna siamea Lam, Senna tora Linn, Leonurus sibiricus Linn was used to make 500 mg disintegrating tablets using the direct compression method (Monton CH, et al., 2014). Allergic asthma is treated with a crude peanut extract of Arachis hypogaea found in a fast-dissolving herbal tablet with a good disintegration time (14-46 sec) (Aswathy KN, et al., 2022). It was found that manufactured 200 mg herbal fast disintegrating tablets of Fagonia schweinfurthii were safe and displayed strong antihistaminic action based on in-vitro and ex-vivo investigations (Puri D, et al., 2018).

The direct compression method was used to manufacture disintegrating tablets from 53 mg of extract powder of the selected plant’s Allium cepa, Cinnamomum zeylanicum, Rheum ribes, Syzygium aromaticum, Sinapis alba, Trigonella foenumgraecum, and Zingiber officinale (Mahran M, et al., 2020).

Techniques for the preparation of fast dissolving tablets

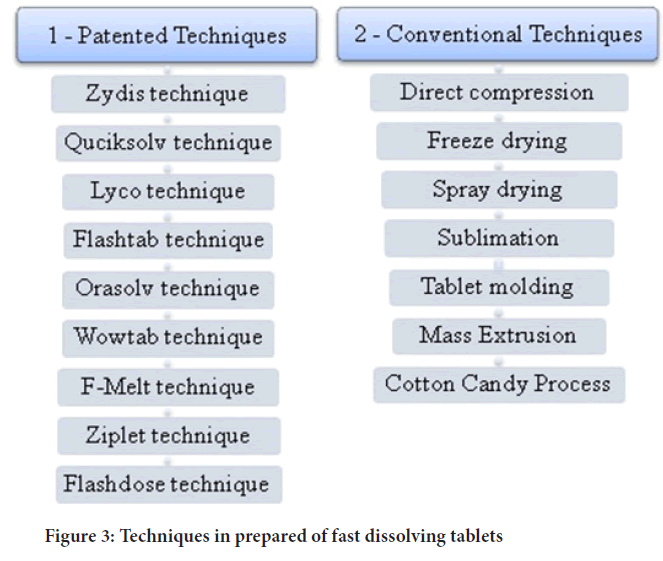

The techniques used to make fast dissolving tablets can be divided into two categories (Figure 3) (Bandari S, et al., 2014; Rada SK and Kumari A, 2019), namely, patented techniques and conventional techniques (Table 2). Below mentioned belong to conventional techniques-

| Technique | Basis | Patent proprietor | Marketed preparation |

|---|---|---|---|

| Zydis | Freeze drying | R.P.Scherer Inc. | Feldene melt (piroxicam 10 and 20 mg). Claritin reditab (loratidine 10 mg) |

| Quicksolv | Lyophilization | Janseen pharmaceutica | Propulsid quicksolv (Cisapride) |

| Lyoc | Freeze drying | Farmlyoc | Spanslof lyoc (Phloruglucinol hydrate) |

| Flashtab | Multiparticulate compressed tablets | Ethypharm | Nurofen flash tab (ibuprofen) |

| Orasolv | Compressed tablets | Cima labs Inc. | Remeron soltab (Mirtazepine 15 mg, 30 mg, and 45 mg) |

| Wowtab | Compressed molded tablets | Yamanouchi pharmacy technologies, Inc. | Benadryl allergy , GasterD (famotidine), sinus fastmelt (OTC), cold fastmelt (OTC) |

| F-Melt | Molding | Fujichemical Ltd. | Aspirin, Vitamin c, Acetaminophen |

| Ziplets | Molding | Eurand | Cibalgina duefast (Ibuprofen) |

| Flashdose | Cotton candy process | Fuisz technology Ltd. | Relivia flash dose (Tramadol HCl) |

Table 2: Patented techniques of FDTs

Figure 3: Techniques in prepared of fast dissolving tablets

Direct compression

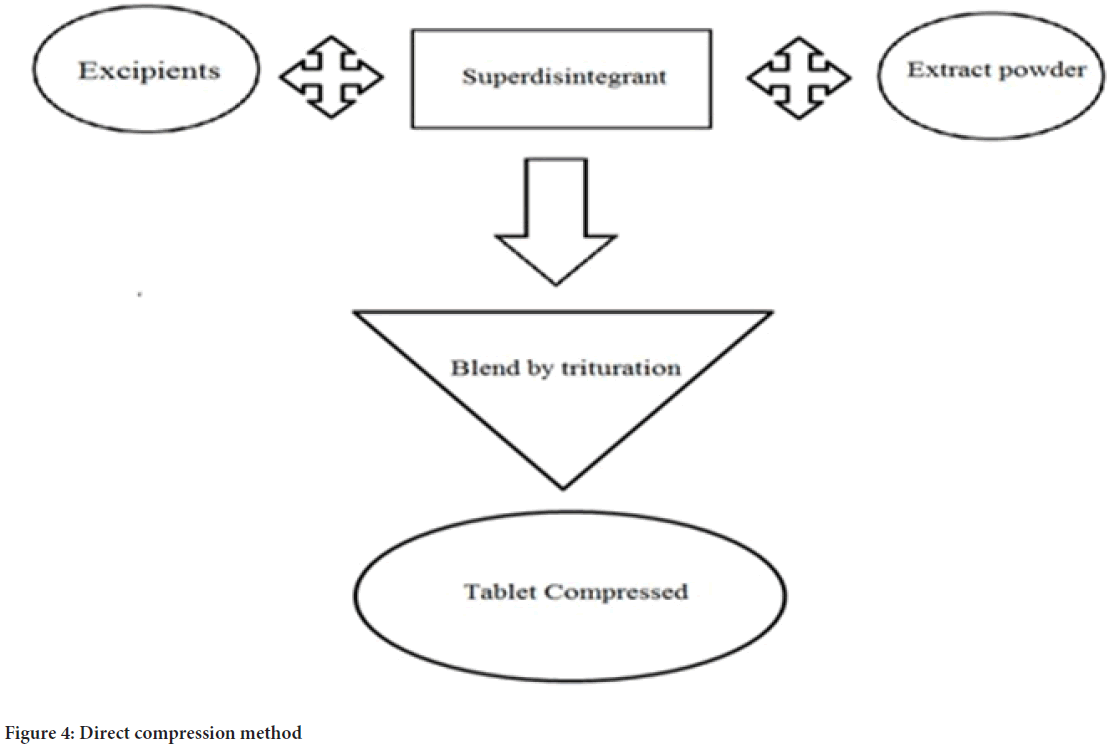

This technique follows blending of the API with excipients and compressing the finished tablets) (Figure 4) (Rajput M, et al., 2012).

Figure 4: Direct compression method

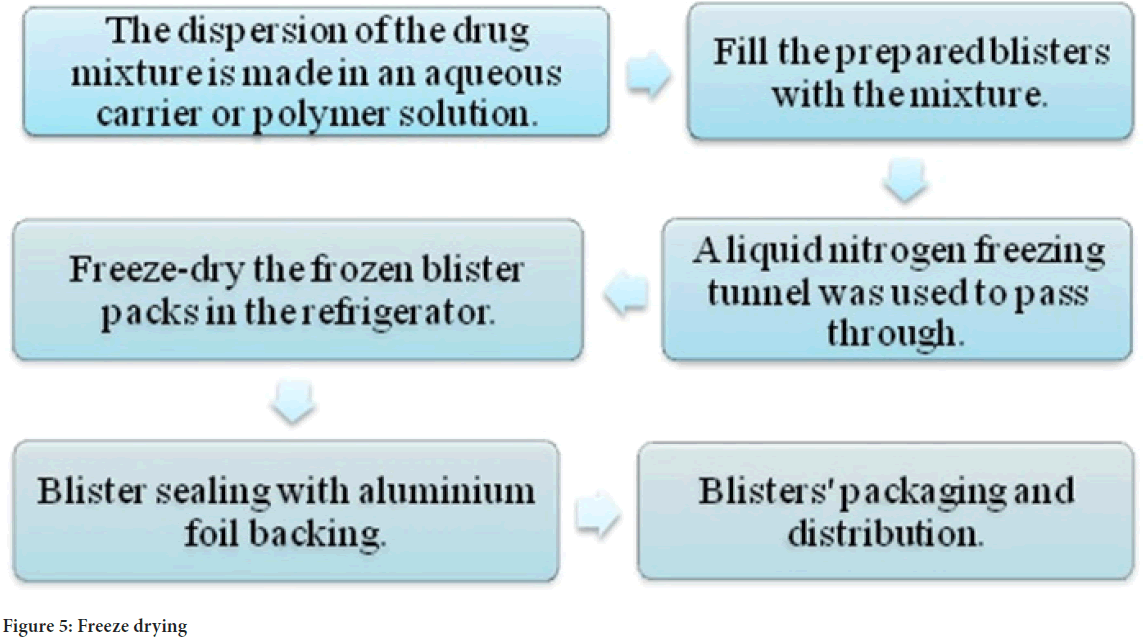

Freeze drying (Lyophilization)

It is a dehydration technique based on the sublimation of water. Frozen sample is placed under a vacuum in order to remove water or other solvents from the sample, allowing the ice to change directly from a solid to a vapor without passing through a liquid phase. (Figure 5) (Habib W, et al., 2000).

Figure 5: Freeze drying

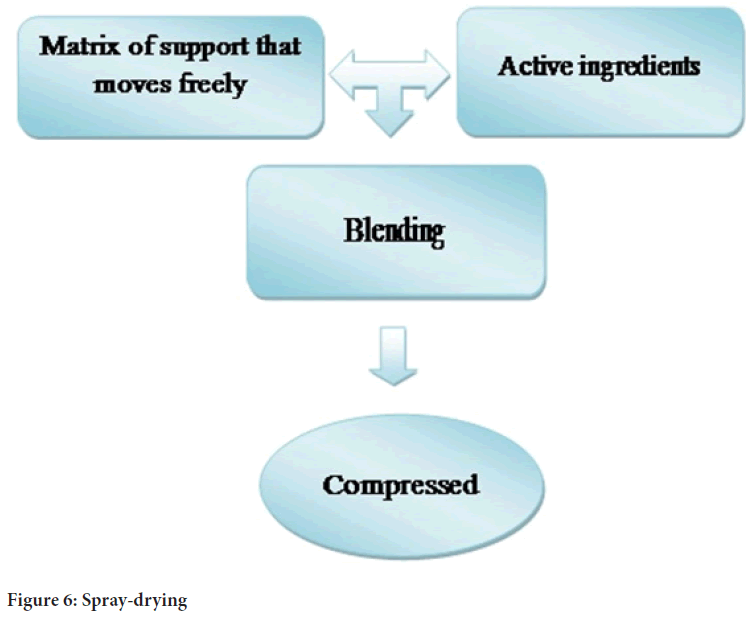

Spray-drying

It is a technique in which the transformation of a liquid feed into a dry and solid state by spraying the feed through a heated drying medium evaporating the water occurs (Figure 6) (RoshanRai R, et al., 2012).

Figure 6: Spray-drying

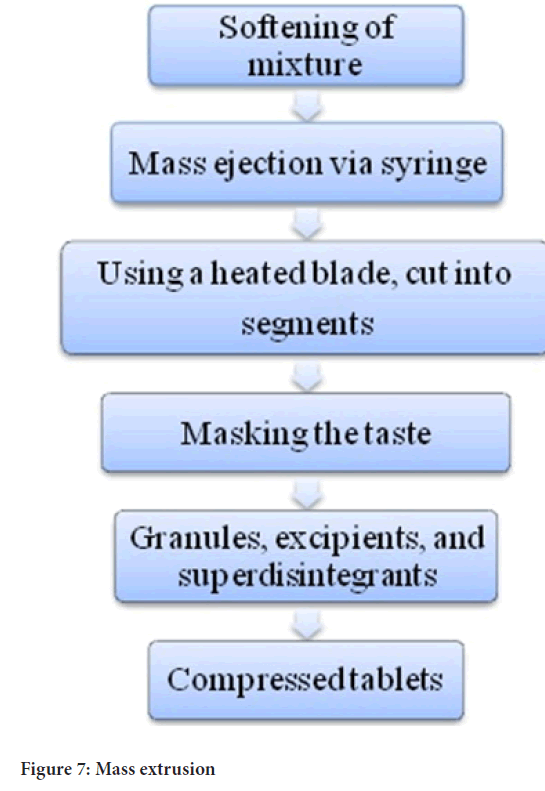

Mass extrusion

It is a technique in which the sample or the material undergoes deformation by the application of force causing the sample to flow through orifice (Figure 7) (Ito A and Sugihara M, 1996).

Figure 7: Mass extrusion

Conclusion

Medicinal plants are considered to gold mine of components that are considered to be therapeutically active. These medicinal plants are used since ancient time for treatment of various ailments. In most of the cases weather we are discussing traditional system of medicine, folklore practice or, Ayurveda combination of herbal components is one on of the widely used preparation. These preparations are intended to be used for treatment of various ailments and are considered to be polyherbal formulations. With patient outcomes concordance, FDTs have possible advantages over existing dose forms; simplicity, bioavailability, and the speedy onset of action have caught the attention of multiple marketers for over a generation. The disintegration characteristic and disintegration rate of the manufactured herbal fast disintegrating tablets are excellent.

References

- Allen L, Ansel HC. Ansel's pharmaceutical dosage forms and drug delivery systems. Lippincott Williams and Wilkins; 2013.

- Wal A, Wal P, Shukla S, Srivastava A. A Comprehensive review on the medicinal plants for the treatment of headache. Int J Pharm Res. 2021; 13(3).

- Jain NK, Sharma SN. A textbook of professional pharmacy. New Delhi: VallabhPrakashan. 1998; 4: 83-89.

- Yadav ND, Pingale PL, Tatane SR. Comparative study on effect of natural and artificial superdisintegrants in the formulation of fast dissolving aspirin tablet. J pharm res. 2010; 3(7): 1594-1597.

- Ratnaparkhi MP, Mohanta GP, Upadhyay L. Review on: Fast dissolving tablet. J pharm res. 2009; 2(1): 5-12.

- Pahwa R, Piplani M, Sharma PC, Kaushik D, Nanda S. Orally disintegrating tablets-Friendly to pediatrics and geriatrics. Arch Appl Sci Res. 2010; 2(2): 35-48.

- Kumar VD, Sharma I, Sharma V. A comprehensive review on fast dissolving tablet technology. J Appl Pharm Sci. 2011; 5(1): 50-58.

- Beneke CE, Viljoen AM, Hamman JH. Polymeric plant-derived excipients in drug delivery. Molecules. 2009; 14(7): 2602-2620.

[Crossref] [Google scholar] [Pubmed]

- Kumar SA, Vivek D, Vandana A. Role of natural polymers used in floating drug delivery system. J Pharm Sci Innov. 2012; 1(3): 11-5.

- Bruscato FN, Danti AG, August DG. Pharmaceutical tablets containing chitin as a disintegrant. United States patent US 4,086,335. 1978.

- Batham P, Kalichman SG, Osborne BE. A 52-week oral toxicity study of gellan gum in the beagle dog. Bio-research laboratories Ltd., Montreal, Canada. 1986.

- Shirwaikar A, Shirwaikar A, Prabu SL, Kumar GA. Herbal excipients in novel drug delivery systems. Indian J Pharm Sci. 2008; 70(4): 415.

[Crossref] [Google scholar] [Pubmed]

- Setia A, Goyal N, Kansal S. Formulation and evaluation of ciprofloxacin hydrochloride dispersible tablets using natural substances as disintegrates. Der Pharmacia Sinica. 2011; 2(1): 36-39.

- Malviya R, Srivastava P, Kulkarni GT. Applications of mucilages in drug delivery-a review. Adv Biol Res. 2011; 5(1): 1-7.

- Prabhu KH, Omer S, Rajanna SG, Pranesh KP. Formulation and evaluation of mouth disintegrating tablets of famotidine by using Hibiscus rosa-sinensis mucilage and treated agar. Int J Res Ayurveda Pharm. 2010; 1(2): 497-505.

- Rinaudo M. Chitin and chitosan: Properties and applications. Prog Polym Sci. 2006; 31(7): 603-632.

- Kumar R, Patil S, Patil MB, Patil SR, Paschapur MS. Isolation and evaluation of disintegrant properties of fenugreek seed mucilage. Int J Pharmtech Res. 2009; 1(4): 982-996.

- Antony PJ, Sanghavi NM. A new disintegrant for pharmaceutical dosage forms. Drug Dev Ind Pharm. 1997; 23(4): 413-415.

- Lieberman H, Lachman L, Schwartz JB. Pharmaceutical dosage forms tablets volumes. Informa Healthcare. 1989.

- Singh B. Psyllium as therapeutic and drug delivery agent. Int J Pharm. 2007; 334(1-2): 1-4.

[Crossref] [Google scholar] [Pubmed]

- Ghenge G, Pande SD, Ahmad A, Jejurkar L, Birari T. Development and characterisation of fast disintegrating tablet of amlodipine besylate using mucilage of Plantago ovata as a natural superdisintegrant. Int J PharmTech Res. 2011; 3(2): 938-945.

- Kulkarni U, Rao NG. Design and development of aceclofenac fast dissolving tablets by novel hole technology: A novel approach to decrease the disintegration time and increase the patient compliance. Drug Invent Today. 2011; 3(6).

- Malik K, Arora G, Singh I. Locust bean gum as superdisintegrant-formulation and evaluation of nimesulide orodispersible tablets. Polim Med. 2011; 41(1): 17-28.

[Google scholar] [Pubmed]

- Alam MT, Parvez N, Sharma PK. FDA-approved natural polymers for fast dissolving tablets. J Pharm. 2014: 952970.

[Crossref] [Google scholar] [Pubmed]

- Ravi KN, Sachin R, Mirtyunjaya B. Evaluation of disintegrating properties of Mangifera indica. RGUHS J Pharm Sci. 2011; 1(1): 11-20.

- Prabakaran L, Sendhil D. Formulation development of patient friendly dosage form: All in one natural excipient as binder, diluent and disintegrant. Int J Pharm Pharm Sci. 2011; 3(supplement 2): 97-102.

- Nagar M, Yadav AV. Cinnarizine orodispersible tablets: A chitosan based fast mouth dissolving technology. Int J Pharmtech Res. 2009; 1(4): 1079-1091.

- Jha AK, Chetia D. Development of natural gum based fast disintegrating tablets of glipizide. Asian J Pharm. 2012; 6(4).

- Suresh S, Senthil A, Manikandan C, Ravikumar N, Swamy VB. Formulation and evaluation of mouth dissolving tablet of amlodipine besylate. Int Res J Pharm. 2011; 2(9): 161-165.

- Sharma V, Arora V, Ray C. Use of natural superdisintegrant in mouth dissolving tablet-an emerging trend. Int bull drug res. 2010; 1(2): 46-54.

- Sukhavasi S, Kishore VS. Formulation and evaluation of fast dissolving tablets of amlodipine besylate by using fenugreek seed mucilage and Ocimum basilicum gum. Int Curr Pharm. 2012; 1(9): 243-249.

- Taksande JB, Murade SS, Trivedi RV, Umekar MJ. Formulation and characterization of lornoxicam fast dissolving tablet using natural super disintegrants. Int J Res Pharm Biomed Sci. 2013; 4(2): 459-464.

- Prajapati ST, Patel MV, Patel CN. Preparation and evaluation of sublingual tablets of zolmitriptan. Int J Pharm Investig. 2014; 4(1): 27.

[Crossref] [Google scholar] [Pubmed]

- Malviya R, Srivastava P, Bansal M, Sharma PK. Mango peel pectin as a superdisintegrating agent. J Sci Ind Res. 2010; 69: 688-690.

- Kaur L, Bala R, Kanojia N, Nagpal M, Dhingra GA. Formulation development and optimization of fast dissolving tablets of aceclofenac using natural superdisintegrant. ISRN Pharm. 2014.

[Crossref] [Google scholar] [Pubmed]

- Kishore VS, Rao BT, Pavani K, Nagasen D, Varma KR, Gowtham D. Plantago ovata seeds and bhringaraj leaves as superdisintegrants: Formulation and evaluation of sotalol hydrochloride orodispersible tablets. Int j pharm chem biol sci. 2013; 3(4).

- Bharathi A, Ramakrishna V, Sowjanya K, Deepthi KS. Formulation development and in-vitro evaluation of orally disintegrating tablets of amlodipine besylate. Int J Res Pharm Chem. 2012; 2(4): 1029-1034.

- Kapoor M, Sharma A, Verma A, Devi R, Kumar A. Fast dissolving tablets: A concise review. Ind Res J Pharm and Sci. 2017; 4(1): 895-906.

- Jhansi M. Formulation and evaluation of domperidone fast dissolving tablets using natural superdisintegrants. Int j res pharm nano sci. 2013; 2(2): 152-157. [Crossref]

- Ravi KN, Sachin R, Mirtyunjaya B. Evaluation of disintegrating properties of mangiferaindica. RGUHS J Pharm Sci. 2011; 1(1): 11-20.

- Jayapirakasam SV, Prabakaran L, Donthireddy BR. Original research formulation development and characterization of Hibiscus rosa-sinesis dry leaves mucilage as smart polymer for pharmaceutical use. Int J Appl Res Nat Products. 2008; 8(2): 28-36.

- Soni A, Raju L. Formulation and evaluation of fast disintegrating tablet containing hydrochlorothizide. Indian J Pharm Pharmacol. 2015; 2(2): 119-133.

- Londhe VY, Umalkar KB. Formulation development and evaluation of fast dissolving film of telmisartan. Indian J Pharm Sci. 2012; 74(2): 122.

[Crossref] [Google scholar] [Pubmed]

- Maurya H, Kumar T. Formulation, standardization, and evaluation of polyherbal dispersible tablet. Int J Appl Pharm. 2019; 7: 158-167.

- Kagalkar AA, Nanjwade BK, Bagli RS. Development and evaluation of herbal fast dissolving tablets of Tectona grandis Linn. Int J Pharm Sci Rev Res. 2014; 3(1): 6-14.

- Kagalkar AA, Nanjwade BK, Srichana T. Development and evaluation of fast dissolving tablets of Bauhenia veriagata Linn. World J Pharm Pharm Sci. 2017; 6(5): 1027-1039.

- Monton CH, Saingam WO, Suksaeree JI, Sakunpak AP, Kraisintu KR. Preformulation and physical properties study of fast disintegrating tablets from Thai traditional formula. Int J Pharm Pharm Sci. 2014; 6: 431-434.

- Aswathy KN, Asdaq SM, Saritha CK, Thomas L, Haridas N, Viswanad V, et al. Formulation and in-vitro characterization of fast-disintegrating herbal extract sublingual immunotherapy tablet for peanut-induced allergic asthma. Saudi J Biol Sci. 2022; 29(3): 1283-1297.

[Crossref] [Google scholar] [Pubmed]

- Puri D, Bhandari A, Gaur PK, Yasir M, Kumar SS, Choudhary D, et al. Formulation of herbal fast disintegrating tablets and its ex-vivo study for anti-histaminic activity in guinea pig ileum. Curr Clin Pharmacol. 2018; 13(2): 128-135.

[Crossref] [Google scholar] [Pubmed]

- Mahran M, Elgarhy OH, Hussein A, Ahmed AS, Taha MA, Alaaeldin E. Fast disintegrating tablets of spray dried poly-herbal extract: A promising hypoglycemic and diabetic wound healing activity. J Adv Biomed and Pharm Sci. 2020; 3(1): 23-30.

- Bandari S, Mittapalli RK, Gannu R. Orodispersible tablets: An overview. Asian J Pharm. 2014; 2(1).

- Rada SK, Kumari A. Fast dissolving tablets: Waterless patient compliance dosage forms. J drug deliv ther. 2019; 9(1): 303-317.

- Rajput M, Sharma R, Kumar S, Jamil F, Sissodia N, Sharma S. Pulsatile drug delivery system: A review. Int j res pharm biomed sci. 2012; 3(1): 118-124.

- Habib W, Khankari R, Hontz J. Fast-dissolve drug delivery systems. Crit Rev Ther Drug Carrier Syst. 2000; 17(1).

[Crossref] [Google scholar] [Pubmed]

- RoshanRai R, Chirra P, Thanda V. Fast dissolving tablets: A novel approach to drug delivery-a review. Int J preclin pharma res. 2012; 3(1): 23-32.

- Ito A, Sugihara M. Development of oral dosage form for elderly patient: Use of agar as base of rapidly disintegrating oral tablets. Chem Pharm Bull (Tokyo). 1996; 44(11): 2132-2136.

[Crossref] [Google scholar] [Pubmed]

Author Info

Somesh Shukla*Citation: Shukla S: A Comprehensive Review on the Potential of Polyherbal Formulation in a Fast-Disintegrating Tablet

Received: 25-Jan-2023 Accepted: 08-Feb-2023 Published: 15-Feb-2023, DOI: 10.31858/0975-8453.14.2.113-121

Copyright: This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

ARTICLE TOOLS

- Dental Development between Assisted Reproductive Therapy (Art) and Natural Conceived Children: A Comparative Pilot Study Norzaiti Mohd Kenali, Naimah Hasanah Mohd Fathil, Norbasyirah Bohari, Ahmad Faisal Ismail, Roszaman Ramli SRP. 2020; 11(1): 01-06 » doi: 10.5530/srp.2020.1.01

- Psychometric properties of the World Health Organization Quality of life instrument, short form: Validity in the Vietnamese healthcare context Trung Quang Vo*, Bao Tran Thuy Tran, Ngan Thuy Nguyen, Tram ThiHuyen Nguyen, Thuy Phan Chung Tran SRP. 2020; 11(1): 14-22 » doi: 10.5530/srp.2019.1.3

- A Review of Pharmacoeconomics: the key to “Healthcare for All” Hasamnis AA, Patil SS, Shaik Imam, Narendiran K SRP. 2019; 10(1): s40-s42 » doi: 10.5530/srp.2019.1s.21

- Deuterium Depleted Water as an Adjuvant in Treatment of Cancer Anton Syroeshkin, Olga Levitskaya, Elena Uspenskaya, Tatiana Pleteneva, Daria Romaykina, Daria Ermakova SRP. 2019; 10(1): 112-117 » doi: 10.5530/srp.2019.1.19

- Dental Development between Assisted Reproductive Therapy (Art) and Natural Conceived Children: A Comparative Pilot Study Norzaiti Mohd Kenali, Naimah Hasanah Mohd Fathil, Norbasyirah Bohari, Ahmad Faisal Ismail, Roszaman Ramli SRP. 2020; 11(1): 01-06 » doi: 10.5530/srp.2020.1.01

- Manilkara zapota (L.) Royen Fruit Peel: A Phytochemical and Pharmacological Review Karle Pravin P, Dhawale Shashikant C SRP. 2019; 10(1): 11-14 » doi: 0.5530/srp.2019.1.2

- Pharmacognostic and Phytopharmacological Overview on Bombax ceiba Pankaj Haribhau Chaudhary, Mukund Ganeshrao Tawar SRP. 2019; 10(1): 20-25 » doi: 10.5530/srp.2019.1.4

- A Review of Pharmacoeconomics: the key to “Healthcare for All” Hasamnis AA, Patil SS, Shaik Imam, Narendiran K SRP. 2019; 10(1): s40-s42 » doi: 10.5530/srp.2019.1s.21

- A Prospective Review on Phyto-Pharmacological Aspects of Andrographis paniculata Govindraj Akilandeswari, Arumugam Vijaya Anand, Palanisamy Sampathkumar, Puthamohan Vinayaga Moorthi, Basavaraju Preethi SRP. 2019; 10(1): 15-19 » doi: 10.5530/srp.2019.1.3