Review Article - (2024) Volume 15, Issue 3

Abstract

This analysis focuses on how robotics and Artificial Intelligence (AI) is becoming more and more important in the pharmaceutical industry. It might be especially helpful for India, a country with a big and expanding population and little access to healthcare resources in its rural areas. AI uses quick and sophisticated algorithms to combine vast volumes of data. This enables the software to swiftly adjust the data characteristics’ pattern. It could potentially clash with the majority of the health system’s components, from detection to prevention and deterrent. Over the past few years, there has been a noticeable increase in the application of AI and robots in the healthcare industry. Activities such as drug development, clinical trials, and quality assurance are some of the tasks that may be managed with great efficiency using artificial intelligence in urban and rural areas across the country. Artificial Intelligence (AI) in the pharmaceutical industry offers benefits such as privileged patient treatment during clinical trials, safe working environments with reduced human infection risk, and efficiently managed operational duties. The healthcare industry, which is among the largest and most dynamic in the world, has a tendency to advance development through innovation and modernization. This profitable business is anticipating a major breakthrough in the future that will generate intelligent machines that think and act like people. Future applications of AI and robots in healthcare include, drug development, identification of fatal illnesses, remote prescription monitoring, remote prescription monitoring and geriatric care, etc. However, given the cost, the shortage of skilled labor, and people’s ingrained mindset, the viability of deploying robotics in the pharmaceutical industry may be called into doubt. The largest obstacle is transferring this technology to industrial areas so that these facilities may serve a greater portion of the nation’s population. The purpose of this review is to identify the main obstacles and assess how viable and adaptable these new technologies are in the Indian context.

Keywords

Artificial intelligence, Robotics, Automation, Drug discovery, Clinical trials

Introduction

Four major categories can be used to group AI applications in healthcare: Expressive, analytical, prognostic, and prescriptive. The only way to close the skills gap in the healthcare industry is to increase the application of artificial intelligence. AI makes it simple to diagnose common health problems, which lessens the burden for skilled medical personnel and lowers treatment costs in India (Deo N and Anjankar A, 2023). By 2035, AI is expected to boost India’s economy by a whopping 957 billion USD. (2017, Accenture) (Chatterjee S and Dohan MS, 2021). AI will also show to be a useful tool in lessening the nation’s economic inequality. According to a global survey report (Chatterjee S and Dohan MS, 2021), new jobs may be created as a result of impending AI-integrated healthcare projects, potentially offsetting the apparent decline of jobs caused by AI. The following are AI’s main areas of importance in healthcare:

Machine learning

The application and creation of whole systems capable of learning and adapting from patterns in data without the need for explicit instructions.

Natural language processing

An area of artificial intelligence that focuses on the analysis and modification of textual or spoken data produced by humans.

Robotic process automationAn automation technology that uses software to mimic the back office tasks of human workers, such as extracting data, filling the forms, moving files, etc. In addition, AI also supports the healthcare system in diagnosis and treatment applications, patient engagement and adherence, and administrative applications (Davenport T and Kalakota R, 2019).

A study by Grand View Research predicts that the global market for pharmaceutical robotics will reach USD 357.9 million by 2030. The market is expected to expand at a Compound Annual Growth Rate (CAGR) of 9.2% from 2022 to 2030. This growth can be attributed to several factors, including the ability of automated systems to rapidly and safely perform repetitive tasks (Wani NU, et al., 2013). The pandemic caused a huge acceleration in the rate of adoption of pharmaceutical robots. Robotics has gained a worldwide attention in recent times especially in pharmaceutical industry. Robots are designed generally for the industrial use as the production takes place at larger scale in industries. These robotic products termed as ‘Robots’ are generally designed for industrial use playing a very important role right from packaging of medicines to research and development laboratories and for maintaining cleanliness as well. With the advancement in design and functioning of robots, this field of technology has growing rapidly. Orders for robots from North American life sciences companies increased by 69% in 2020 compared to 2019, according to the Robotic Industries Association (RIA), a trade group focused on the robotics industry. The increased demand came from a massively increased need to process test samples and produce testing kits and protective equipment like masks and gloves (Wani NU, et al., 2013).

Other factors like personalized medicine are impacting the demand for pharmaceutical robots. Personalized medicine rests on the idea that some people will respond better to a certain treatment than others, based on their genetic makeup. The concept brings with it a vastly expanded need for testing patient samples and medical formulations. Because personalized medicine implies many more customized medications, packaging and labelling requirements will increase. With personalized medicine, the batch size can be reduced to one dose (Wani NU, et al., 2013). A lower volume per medication added to a higher variety of medicines increases the labor intensity of producing these pharmaceuticals. The combination drives the market demand for robotics (Wani NU, et al., 2013). Robotics are also being used in laboratories to provide efficient working. For example, SciGene which is a robot used for the preparation of Deoxyribonucleic Acid (DNA) samples and Varian’s auto-sampler is a robot used in picking up of test tubes and loading them in an Nuclear Magnetic Resonance (NMR) magnet (Merk F, 2022).

Robots are already playing an increasingly important role in the creation of novel pharmaceuticals. Millions of chemicals are evaluated in High Throughput Screening (HTS) to see which ones could become new medications. The employment of robotics to test these millions of chemicals is required. Robotics, like any other procedure in which a robot substitutes a person performing a repetitive duty, can dramatically speed up this process (Merk F, 2022). For example, in Southern States University, robotic arms are widely used in high-throughput screening operations. High Throughput Screening (HTS) consists of a plate called a microplate: It is a small container which is disposable, and these microplates are made up of plastic, that features a grid of small, open wells acting as miniature test tubes for carrying out the required task. The number of wells differs from microplates to microplates such as modern HTS microplates generally have wells starting from 384, 1,536, 3,456 and 9,600 wells. Using robotics, sensitive detectors, liquid handling devices, and software for processing of data and system control, HTS allows millions of genetic, chemical, or pharmacological tests to be conducted very rapidly. Through this process one can rapidly identify active compounds, antibodies or genes which modulate a particular biomolecular pathway, and these experiments provide starting points for drug design and for understanding the role and interaction of a chosen or particular biochemical process (Merk F, 2022; Kundap S, 2021). In this review, we will take a closer look at the use of robots in the pharmaceutical industry and some of the best pharmaceutical robot use cases and their benefits. Note that one limiting factor in the adoption of robot automation is government regulation. In particular, regulations have so far inhibited the use of self-learning systems and artificial intelligence. The regulators may take time to catch up with the technology. Of course, safety is of paramount importance, so regulation is needed (Wani NU, et al., 2013).

LITERATURE REVIEWAdvantages of robotics

• Efficiency: Robots work quickly and efficiently, without wasting time. Robots can change productivity by increasing without taking breaks.

• Versatility: Packaging applications can vary. Robots are simple to reprogram.

• Advantage of safety: Robots safeguard the integrity of pharmaceutical products as well as the health of employees and patients. Toxic chemicals can be safely mixed using industrial robots.

• Design advantage: In the pharmaceutical business, slim, rapid, and flexible robots are suitable for pick-and-place and assembly tasks. Industrial robots can construct blood sugar kits and other custom orders thanks to vision technology (Swati Y, et al., 2022).

• Reliability: All medication must be tracked and traced throughout the manufacturing process, according to the Food and Drug Administration (FDA). Robots reduce accidents and waste (Bragança S, et al., 2019).

Tirelessness: A robot can complete a 96-hour project in ten hours with greater consistency and higher quality results.• Accuracy: Automated equipment doesn’t need a learning curve to master weighing, blending and tableting of solids or the stirring and filling of liquids. Automation eliminates human error and significantly reduces product defects (Teja LT, et al., 2014).

• Quality: Robots have the potential to significantly improve product quality. Every application is executed with precision and high repeatability.

• Savings: Increased worker safety results in financial savings. Employers have fewer concerns about healthcare and insurance (Bragança S, et al., 2019).

• Reduced contamination risk: Removing people from the screening process reduces the possibility of contamination and dropped samples when handling them in laboratories (Teja LT, et al., 2014).

• Increases productivity: Because of the high-speed operation of robots, it also saves time and increases productivity throughout the day (Bragança S, et al., 2019).

Disadvantages

• Dangers and fears: Although current robots are not thought to have progressed to the point where they pose a threat or danger to society, fears and concerns about robots have been expressed in a variety of books and films. The main theme is that robots’ intelligence and ability to act may surpass that of humans, and that they may develop a conscience and a desire to take over or destroy the human race (Kundap S, 2021).

• Expense: Robots require a significant initial investment, especially when business owners limit their purchases to new robotic equipment. Regular maintenance requirements can also be costly.

• Return on Investment (ROI): The use of industrial robots does not guarantee success. Companies may struggle to meet their objectives if they do not plan ahead of time (Teja LT, et al., 2014).

• Expertise: Employees will need to be trained in programming and interacting with the new robotic equipment. This normally necessitates both time and money.

• Safety: While robots may protect workers from some hazards, their mere presence can cause other safety issues. These new dangers must be taken into account (Deo N and Anjankar A, 2023).

• Unemployment: Some challenges are related to job loss, as the OECD (Organization for Economic Cooperation and Development) estimated in 2019 that 35% of jobs may be seriously affected by automation, and 14% of current jobs may no longer be available due to automation (Kundap S, 2021).

Discussion

Pharmaceutical applications for robots

Organized operational tasks Automated Mobile Robots (AMRs) regularize regular tasks, decrease the physical burden on health workers and make sure that more precise procedures are utilized. These robots can address the shortage of staff, keep a trail of records and place orders on time. They ensure that medicines and other equipment are available as and when needed. Rooms can be quickly cleaned and sanitized and are timely ready for incoming patients by automated robots which enable health professionals to perform other important patient-related jobs. Robots can be efficiently used for making diagnoses of different diseases by using artificial intelligence. The radiologist robots, which are equipped with computational imaging capabilities, are used for making diagnoses with the help of AI through deep learning. These robots are also used for doing diagnosis procedures like Magnetic Resonance Imaging (MRIs) and X-rays and hence are of great advantage for healthcare workers, as it protects them from harmful radiations used in these procedures (Gandu S, et al., 2023).

Drug discovery: One of the major areas where the use of AI can prove to be a boon is the field of drug discovery. It takes about 14 years and an average of 2.6 billion dollars for a new drug to reach the market through conventional procedures, whereas the same can be done using AI in a lesser amount of time. Recently in 2015, the outbreak of the Ebola virus in West Africa and some European countries were controlled with the application of AI which helped to discover an appropriate drug in a very meager time and prevented the outbreak from becoming a global pandemic. In addition to this, it has been proven that it takes very little time to conduct clinical trials of newly discovered drugs using AI. AI can also be used to recognize cardiotoxic and non-cardiotoxic drugs of the anticancer group. It is also capable of identifying probable antibiotics from a list of thousands of molecules and can be used as a medium to discover new antibiotics. These algorithms are also being used to identify the molecule with the potential to combat antimicrobial resistance leading to resistance from antibiotics. Studies are underway to explore the role of AI in combating fast-growing antibiotic resistance (Raje S, et al., 2021) (Figure 1).

Figure 1: Use of robotics in drug discovery

Quality inspection and quality control: Robotic equipment plays a crucial role in testing pharmaceuticals at many stages of the production process. The assaying or testing of samples may involve the disintegration of tablets into powders. An assay may require the dispersion of a powder into a liquid. Solid and liquid ingredients may need to be mixed together to achieve evenness and activate chemical reactions. For high-volume tests on a production line, while a robot could perform such a mixing task, a dedicated machine may perform these mixing and testing tasks. Traditional automation serves well in such a scenario. Robots can be used to fill in the gaps. For example, a robot can load samples into the assaying machine, and also remove the specimens when the test is complete (Wani NU, et al., 2013) (Figure 2).

Figure 2: Efficient execution of AI in clinical trials

Clinical trials: Previously the process of clinical trials was very slow and success rates were very poor. Before the year 2000, the success rate of completing the clinical trials via all three stages, for the candidates was only 13.8% (Builtin, 2020). The execution of AI has reduced the cycle time and has also impacted the production cost and outcome in a positive direction. AI helps in ensuring the continuous flow of clinical trial data and also coding, storing, and managing them. Details of patients saved in the computer can be analysed and the lessons learned can be used for future trials, thus saving time and cost (Shah P, et al., 2019). It also works efficiently to observe the patients consistently and share the data across different computers. The self-learning capacity of AI enhances the accuracy of the trial and foresees the chances of dropouts (Woo M, 2019).

Rajiv Gandhi Cancer Institute and Research Center (RGCI), New Delhi, has completed preliminary clinical trials for SSI-Mantra, a surgical robot that is indigenously built in India. Ever since its launch, RGCI has been instrumental in validating the effectiveness and feasibility of this robotic system under the guidance of Dr. Sudhir Rawal, medical director at RGCI and one of the pioneers of robotic surgeries in India.

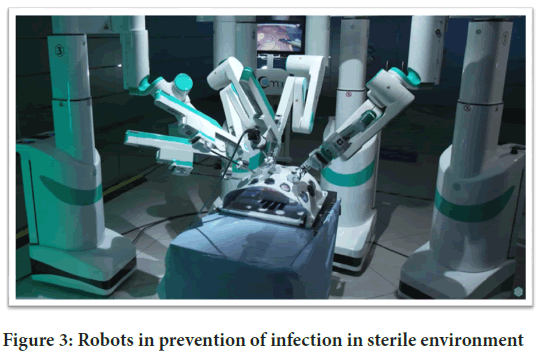

Sterilization and clean rooms: Robotics can be modified to work in sterile conditions. The features of clean room robots prevent the sterile environment from infection (Figure 3). Low flake coatings on the robotic arm, stainless steel fasteners, specific seal materials, and enclosed cables are among these qualities. Robots in clean rooms save money by automating tasks such as inspection, picking and placement, and loading and unloading process tools. The following are some of the advantages of using a robot in a clean room:

Figure 3: Robots in prevention of infection in sterile environment

• Robots help to reduce contamination-related scrap.

• Robots cut down on the need for clean room consumables like bunny suits.

• Robots reduce scrap by reducing the number of pieces that are mishandled or dropped.

• Clean room protocol enforcement and training expenditures are kept to a minimum.

• Robots save money on clean room area by removing lanes and access points that are traditionally required for human clean room workers. Miniature surroundings can also be created for robots. This allows for a more relaxed level of hygiene throughout the rest of the facility [5].

Sterile syringe filling: Stericlean, three-way collaboration between robotics specialist Staubli, factory automation firm, and pharmaceutical manufacturer Sanofi-Aventis, was introduced at Interphex as the market’s only robot arm that can be used in barrier isolation systems. Stericlean has significantly increased our productivity by replacing manual processes.

Biopharma and diagnostic applications: It offers standardised solutions with high throughput and reproducible, accurate results in fields such as genomics, cells and proton sciences, and forensics. It provides pharmaceutical laboratories with automated solutions for cell culture, nucleic acid extraction, normalisation, genotyping, protein purification and analysis, hit picking, Absorption Distribution Metabolism and Excretion (ADME) screening, Polymerase Chain Reaction (PCR) applications, and protein crystallography (Mohapatra DP, et al., 2015; Cao L, et al., 2021; Chapman T, 2003; Hedelind M and Jackson M, 2011; Fiorini P and Botturi D, 2008; Myers B, 1994; Bloss R, 2013; Barrett M, et al., 2012).

Pick and place/handling: According to a study by Global Market Estimates, the delta-style robot is the most often used type of robot for pick and place applications. Delta robots are known for their speed, yet they are limited by the amount of weight they can carry. Since most medications are quite small and lightweight, the Delta robot is ideal for many of the packaging applications found in pharmaceutical production. Selective Compliance Assembly Robot Arm (SCARA) robots are also fast and, for many pharmaceutical pick-and-place operations, are excellent choices. When a larger weight-carrying capacity is needed, articulated arm robots and Cartesian robot arms are used (Wani NU, et al., 2013). Packaging includes not only placing pills and vials into blister packs and boxes, but also the very important task of printing and applying labels. Robots handle this kind of job precisely and tirelessly. Robots equipped with vision systems can remove primary packages from a conveyor belt and place them into secondary packaging such as cartons.

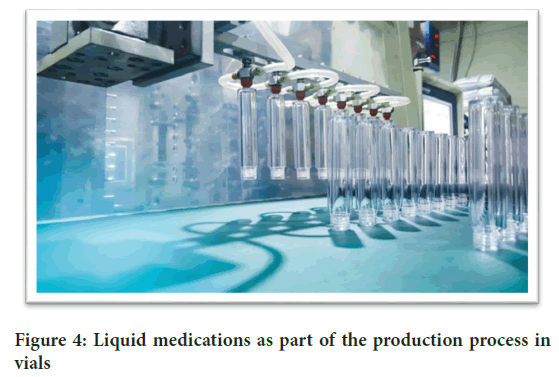

Mixing and dosing: Some liquid medications need to be swirled about in a vial or bottle as part of the production process. A powder may need to be dissolved into a liquid. A robot arm can gently pick up a vial and rotate it according to extremely strict pathway specifications-in a pendulum motion, vertical or horizontal rotation, and many other motions, such as shaking. The repeatability of the motion is crucial to the reliability of the results. Humans find it boring and difficult to repeat precise motions over thousands of repetitions, whereas robots excel at such tasks. For large, bulk production of tablets and other types of medicines, conventional automation in the form of stationary mixers and dosing equipment is most often used. However, robotics can assist the process. For example, Automated Guided Vehicles (AGVs) can supply bulk materials to stationary equipment. An AGV or Automated Mobile Robot (AMR) can transport the ingredients of a medicine from storage to the dispensing machine with little to no human intervention (Wani NU, et al., 2013) (Figure 4).

Figure 4: Liquid medications as part of the production process in vials

Packing/pelletizing: At the end of the production process, finished products need to be packed up to be shipped to customers. Palletizing robots automate this task by grasping boxes or cartons and stacking them onto pallets.

Palletizing robots can optimize stacking to maximize the number of boxes contained per pallet. Ensuring stability in shipping is another optimization criterion. Automatic shrink-wrapping can also be performed by palletizing robots, which aids in securing valuable cargo.

Because the weights of boxes, cartons, and pallets are larger than earlier in the production process, the robot arms tend to be more powerful at this later stage. The type of robot used varies according to the application. If the motions needed are simple, a Cartesian robot may suffice. If maximum flexibility is needed, articulated robot arms can perform complex maneuvers and carry significant weight (Wani NU, et al., 2013) (Figure 5).

Figure 5: Palletizing robots in the task of packing finished products

Challenges and risks

Many challenges occur in the way of adopting robotics in pharmaceutical company. One consideration is having room for the equipment. Although robots make efficient use of workspace, manufacturing floor space is limited and to rearrange things to accommodate the new equipment. No doubt a certain margin of increase in throughput can be achieved within the current size of production operation. On the other hand, to increase production by a considerable amount, there is need to increase the size of facility. Not only increased production space will be needed, but storage space and space for packing and palletizing, too. Another concern might be not seeing the value of robotics for operations. One may find it helpful to talk with people who have seen companies similar to successfully implement robotics. Although discussing things with vendors can be valuable, sometimes a more impartial viewpoint is needed. To help in assessing the value of a robotics solution, robot offers an online investment to assist in estimating savings and ROI.

Conclusion

Although the introduction of robots in Pharmaceuticals is in its infant stage, it offers a lot of opportunities for medical professionals, especially in the urban setting. The significant role of AI in areas like drug discovery, diagnosis of diseases, digital medical consultations, robotic surgeries, remote patient monitoring and prediction of epidemic outbreaks cannot be denied. The emerging role of robotics in Pharmaceutical has been recognized and is gradually being accepted by Indian society. In the present scenario it is not possible to think about implementation and monitoring of health services in the absence of AI and robotics. Many new techniques are underway in the use of robotics in the health sector which may be more cost effective in the future. But the quality of robotic procedures needs to be controlled by establishing a stringent and continuous monitoring system. Use of AI and robotics in pharmaceutical sector in India may prove to be a milestone in improving the present status of healthcare services. It has certainly helped in bridging the gap created by lack of skilled health professionals as well as the huge vacancies of doctors, nurses and paramedical staff. The main challenge is to reach the remote regions of the country with poor infrastructural facilities and lack of advanced technologies. The high cost of using AI and robotics in the healthcare sector stands as the major barrier in the path of reaching the disadvantaged community. Besides this, there are chances of errors and mechanical failures due to improper maintenance arrangements resulting in fatal consequences. The Indian government should support companies to invest in AI and encourage Public Private Partnership (PPP) in the domain of AI and health. The ethical issues must be addressed by the policy makers to enhance the use of AI and robotics in the healthcare sector. After considering the various facts and practicality, it can be said that the use of robotics in India should be expanded in a phased manner initiating with the reputed and equipped firms. It is viable only if used judiciously with a standardized reporting and monitoring system in place.

References

- Deo N, Anjankar A. Artificial Intelligence with robotics in healthcare: A narrative review of its viability in India. Cureus. 2023; 15(5): 1-15.

[Crossref] [Google Scholar] [PubMed]

- Chatterjee S, Dohan MS. Artificial intelligence for healthcare in India: Policy initiatives, challenges, and recommendations. Int J Healthc Inf Syst Inform. 2021; 16(1): 1-11.

- Davenport T, Kalakota R. The potential for artificial intelligence in healthcare. Future Healthc J. 2019; 6(2): 94-98.

[Crossref] [Google Scholar] [PubMed]

- Wani NU, Taneja K, Adlakha N. Health system in India: Opportunities and challenges for enhancements. Int J Business Manag. 2013; 9: 74-82.

- Merk F. Pharmaceutical robots: A comprehensive overview. Robot Tech. 2022.

- Kundap S. Robotics in pharmaceutical industry. Indo Am J Pharm Res. 2021;11(10):1-70.

- Swati Y, Shilpa B, Hashweta G, Yashodita D. Robotics to grow sharply in pharmaceutical industry. Adv Robot Autom. 2022; 11(6): 1-3.

- Bragança S, Costa E, Castellucci I, Arezes PM. A brief overview of the use of collaborative robots in industry 4.0: Human role and safety. Occup Environ Safety Health. 2019; 202: 641-650.

- Teja LT, Keerthi P, Datta D, Babu NM. Recent trends in the usage of robotics in pharmacy. Indian J Res Pharm Biotech. 2014; 2(1): 1038-1043.

- Gandu S, Gandla K, Vaishnavi M, Repudi L. A review on implementation of automation in the pharmaceutical industries. World J Adv Res Rev. 2023; 18(2): 606-615.

- Raje S, Reddy N, Jerbi H, Randhawa P, Tsaramirsis G, Shrivas NV, et al. Applications of healthcare robots in combating the COVID-19 pandemic. Appl Bionics Biomech. 2021; 2021: 1-12.

[Crossref] [Google Scholar] [PubMed]

- AI in healthcare: Uses, examples and benefits. Builtin. 2020.

- Shah P, Kendall F, Khozin S, Goosen R, Hu J, Laramie J, et al. Artificial intelligence and machine learning in clinical development: A translational perspective. NPJ Digit Med. 2019; 2: 1-10.

[Crossref] [Google Scholar] [PubMed]

- Woo M. An AI boost for clinical trials. Nature. 2019; 573(7775): S100-S102.

[Crossref] [Google Scholar] [PubMed]

- Mohapatra DP, Mohapatra MM, Chittoria RK, Friji MT, Kumar SD. The scope of mobile devices in health care and medical education. Int J Adv Med Health Res. 2015; 2(1): 3-8.

- Cao L, Russo D, Lapkin AA. Automated robotic platform in design and development of formulations. AIChE J. 2021; 67(5): 1-17.

- Chapman T. Lab automation and robotics: Automation on the move. Nature. 2003; 421(6923): 661-663.

[Crossref] [Google Scholar] [PubMed]

- Hedelind M, Jackson M. How to improve the use of industrial robots in lean manufacturing systems. J Man Tech Manage. 2011; 22(7): 891-905.

- Fiorini P, Botturi D. Introducing service robotics to the pharmaceutical industry. Intel Serv Robotics. 2008; 1: 267-280.

- Myers B. Key issues for establishing a robotics laboratory in the pharmaceutical industry. J Automat Chem 1994; 16(4): 117-119.

- Bloss R. Review of new robot designs and the rise of remote programming in manufacturing technology. Ind Robot: An Int J. 2013; 40(3): 213-217.

- Barrett M, Oborn E, Orlikowski WJ, Yates J. Reconfiguring boundary relations: Robotic innovations in pharmacy work. Organization Sci. 2012; 23(5): 1448-66.

Author Info

Sandip Suresh Khandagale*, Nalawade Omkar Bappasaheb, Aarti Suresh Khose, Priyanka Kshirsagar, Pratiksha Nemane and Rohini Haribhau ThubeCitation: Khandagale SS: Role of Pharmaceutical Automation and Robotics in Pharmaceutical Industry: A Review

Received: 15-Feb-2024 Accepted: 11-Mar-2024 Published: 18-Mar-2024, DOI: 10.31858/0975-8453.15.3.131-135

Copyright: This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

ARTICLE TOOLS

- Dental Development between Assisted Reproductive Therapy (Art) and Natural Conceived Children: A Comparative Pilot Study Norzaiti Mohd Kenali, Naimah Hasanah Mohd Fathil, Norbasyirah Bohari, Ahmad Faisal Ismail, Roszaman Ramli SRP. 2020; 11(1): 01-06 » doi: 10.5530/srp.2020.1.01

- Psychometric properties of the World Health Organization Quality of life instrument, short form: Validity in the Vietnamese healthcare context Trung Quang Vo*, Bao Tran Thuy Tran, Ngan Thuy Nguyen, Tram ThiHuyen Nguyen, Thuy Phan Chung Tran SRP. 2020; 11(1): 14-22 » doi: 10.5530/srp.2019.1.3

- A Review of Pharmacoeconomics: the key to “Healthcare for All” Hasamnis AA, Patil SS, Shaik Imam, Narendiran K SRP. 2019; 10(1): s40-s42 » doi: 10.5530/srp.2019.1s.21

- Deuterium Depleted Water as an Adjuvant in Treatment of Cancer Anton Syroeshkin, Olga Levitskaya, Elena Uspenskaya, Tatiana Pleteneva, Daria Romaykina, Daria Ermakova SRP. 2019; 10(1): 112-117 » doi: 10.5530/srp.2019.1.19

- Dental Development between Assisted Reproductive Therapy (Art) and Natural Conceived Children: A Comparative Pilot Study Norzaiti Mohd Kenali, Naimah Hasanah Mohd Fathil, Norbasyirah Bohari, Ahmad Faisal Ismail, Roszaman Ramli SRP. 2020; 11(1): 01-06 » doi: 10.5530/srp.2020.1.01

- Manilkara zapota (L.) Royen Fruit Peel: A Phytochemical and Pharmacological Review Karle Pravin P, Dhawale Shashikant C SRP. 2019; 10(1): 11-14 » doi: 0.5530/srp.2019.1.2

- Pharmacognostic and Phytopharmacological Overview on Bombax ceiba Pankaj Haribhau Chaudhary, Mukund Ganeshrao Tawar SRP. 2019; 10(1): 20-25 » doi: 10.5530/srp.2019.1.4

- A Review of Pharmacoeconomics: the key to “Healthcare for All” Hasamnis AA, Patil SS, Shaik Imam, Narendiran K SRP. 2019; 10(1): s40-s42 » doi: 10.5530/srp.2019.1s.21

- A Prospective Review on Phyto-Pharmacological Aspects of Andrographis paniculata Govindraj Akilandeswari, Arumugam Vijaya Anand, Palanisamy Sampathkumar, Puthamohan Vinayaga Moorthi, Basavaraju Preethi SRP. 2019; 10(1): 15-19 » doi: 10.5530/srp.2019.1.3